Roller

This roller will be subjected to induction hardening on the table area and on the sloping areas of the cuts, in order to give greater hardness and durability, in areas where the steel cables will run.

Cart

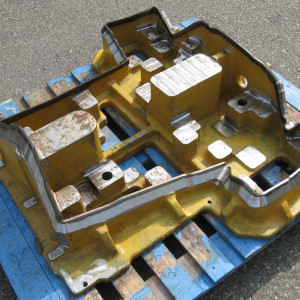

Machine tool pallet

Hardening in the sliding guides limit wear over time and guarantee optimal functioning.

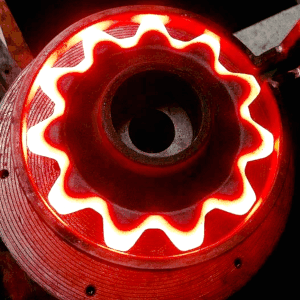

Reheat tests on pinion

In induction hardening only the areas subject to wear are treated, while the remaining part (not hardened) maintains the original elasticity, thus avoiding any breakage of the part itself.

Sectioned detail

A destructive test on the part highlights the area with induction hardening on the teeth.

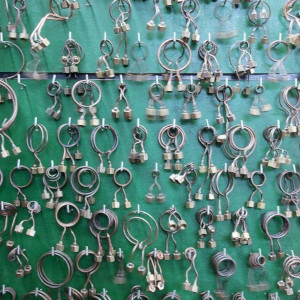

Various part details

Induction hardening is a process that is carried out on mechanical parts of any shape or size.

Trimming mold

Induction hardening on veneer profile. The particularity of the pieces to be treated does not affect the work of the induction hardening which makes it possible to limit deformations and fragility in the most complex section changes.

Pinion

Hardened pinion: its involute gear has been worked "tooth by tooth" to increase its durability.

Wheel with flange

Part details