THE HEAT TREATMENT PROCESS

The heat treatments process consists of thermal heating cycles, carried out in predetermined conditions and temperatures, to which cooling (of varying speeds) must follow, which have the purpose of making the steel assume a crystalline structure that gives it certain mechanical characteristics.There are different types of heat treatments such as: annealing, normalization, distension, tempering, reclamation.

Each of these treatments is performed according to the need and the use that will be operationally required of the part.

The phases that make up the heat treatments are:

THE HEAT TREATMENT PROCESS

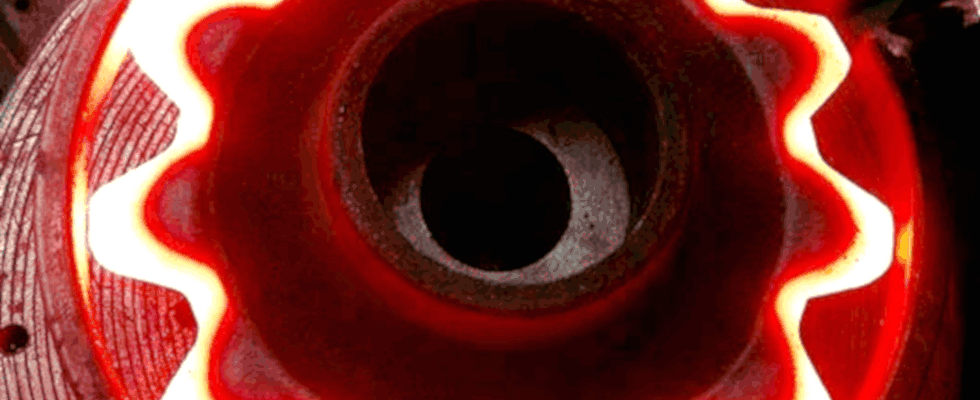

The hardening heat treatment allows the increase of the hardness of a part.The process consists of heating the steel piece to a certain temperature, then cooling it using different techniques [...] Find out more!